Expanded Metal Filter

Expanded metal filters are made from a combination of flattened, regular and/or corrugated expanded aluminum, galvanized steel or stainless steel and regular or corrugated screen wire.

Materials

- Carbon Steel

- Galvanized Steel

- Stainless Steel 304, 316

- Aluminum

Type

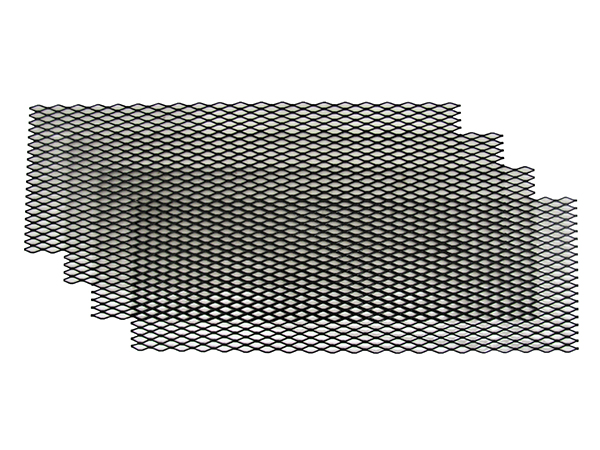

They are typically sheet or cylindrical, but the meshes can be shaped, pressed and welded.

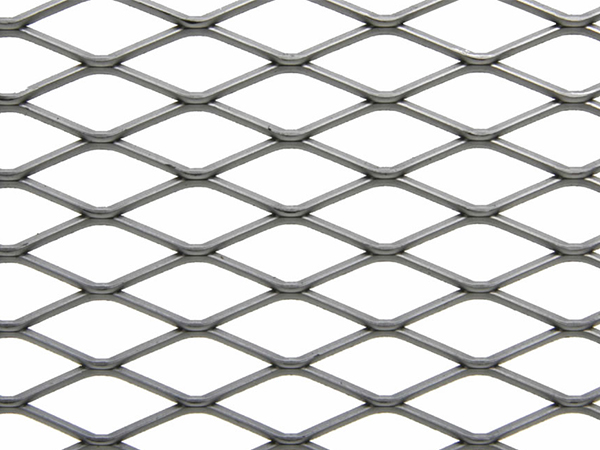

Expanded Metal Filter Element Panel

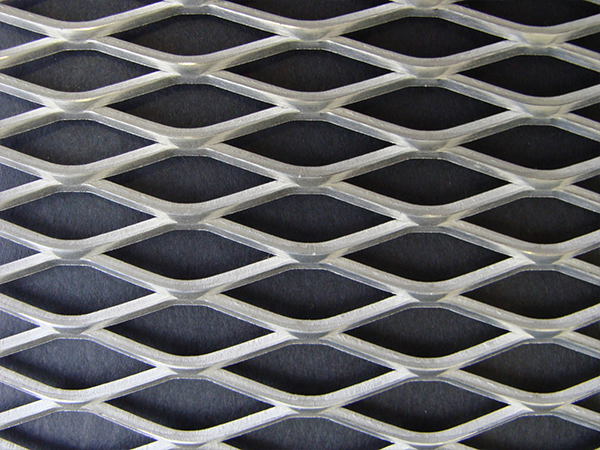

Expanded Metal Filter Element Sheet

Expanded Metal Filter Element Tube

Enzar Metal Company can produce filters and develop new products according to client requirements.

Benefits

- Corrosion resistance

- High shock resistance

- Reinforced performance

- Uniform mesh connection

Expanded metal is that the sheet retains its structural integrity because it has not undergone the stress of having shapes punched in it, and the mesh-like pattern will not unravel. Expanded metal has been stretched rather than punched, reducing scrap metal waste; making it cost-effective.

Application

Expanded metal filters are used mostly in commercial, industrial and OEM facilities. They are used for a variety of applications including heating, air conditioning and other hvac requirements, grease filters, oil or water mist control, large particulate collection or heavy particulate collection, areas where filters are exposed to outside weather conditions, barriers to intrusion of debris, insects or animals, conditions where maximum air flow is required and small particle control is not the primary concern.

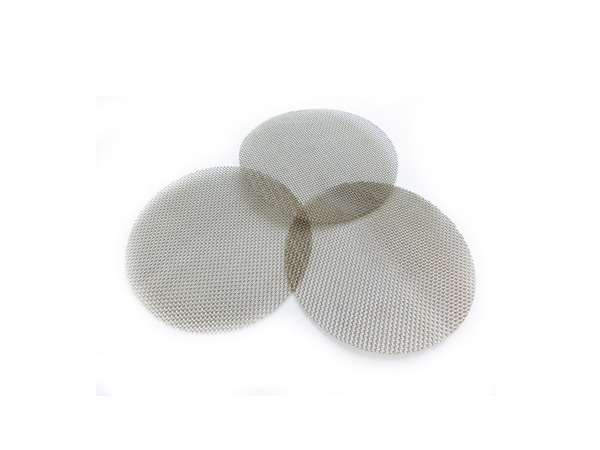

- Mini meshes for fine filtration

- Pleated meshes

- Filtration panels for grease, oil and dust filtration

- Fine fabric gauzes for microfiltration

- Larger meshes are available for strengthening, retention and sorting